The P stands for proportional control, I for integral control and D for derivative control. This is also what is called a three term controller.

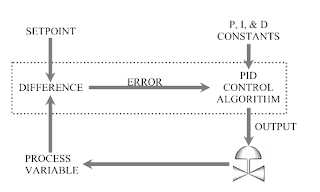

The basic function of a controller is to execute an algorithm (electronic controller) based on the control engineer's input (tuning constants), the operators desired operating value (setpoint) and the current plant process value. In most cases, the requirement is for the controller to act so that the process value is as close to the setpoint as possible. In a basic process control loop, the control engineer utilises the PID algorithms to achieve this.

The PID control algorithm is used for the control of almost all loops in the process industries, and is also the basis for many advanced control algorithms and strategies. In order for control loops to work properly, the PID loop must be properly tuned. Standard methods for tuning loops and criteria for judging the loop tuning have been used for many years, but should be reevaluated for use on modern digital control systems.While the basic algorithm has been unchanged for many years and is used in all distributed control systems, the actual digital implementation of the algorithm has changed and differs from one system to another.

How a PID Controller Works

The PID controllers job is to maintain the output at a level so that there is no difference (error) between the process variable (PV) and the setpoint (SP).In the diagram shown above the valve could be controlling the gas going to a heater, the chilling of a cooler, the pressure in a pipe, the flow through a pipe, the level in a tank, or any other process control system.

What the PID controller is looking at is the difference (or "error") between the PV and the SP. It looks at the absolute error and the rate of change of error. Absolute error means -- is there a big difference in the PV and SP or a little difference? Rate of change of error means -- is the difference between the PV or SP getting smaller or larger as time goes on.

When there is a "process upset", meaning, when the process variable or the setpoint quickly changes - the PID controller has to quickly change the output to get the process variable back equal to the setpoint. If you have a walk-in cooler with a PID controller and someone opens the door and walks in, the temperature (process variable) could rise very quickly. Therefore the PID controller has to increase the cooling (output) to compensate for this rise in temperature.

Once the PID controller has the process variable equal to the setpoint, a good PID controller will not vary the output. You want the output to be very steady (not changing). If the valve (motor, or other control element) are constantly changing, instead of maintaining a constant value, this could case more wear on the control element.

So there are these two contradictory goals. Fast response (fast change in output) when there is a "process upset", but slow response (steady output) when the PV is close to the setpoint.

Note that the output often goes past (over shoots) the steady-state output to get the process back to the setpoint. For example, a cooler may normally have it's cooling valve open 34% to maintain zero degrees (after the cooler has been closed up and the temperature settled down). If someone opens the cooler, walks in, walks around to find something, then walks back out, and then closes the cooler door -- the PID controller is freaking out because the temperature may have raised 20 degrees! So it may crank the cooling valve open to 50, 75, or even 100 percent -- to hurry up and cool the cooler back down -- before slowly closing the cooling valve back down to 34 percent.

proportional & derivative control.pdf